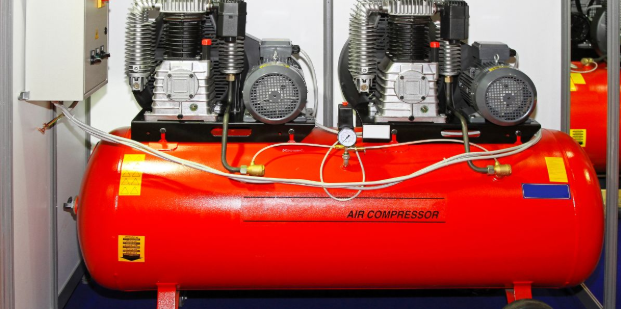

Industrial compressors are vital to numerous operations, from manufacturing facilities to HVAC systems. These machines serve as the backbone of various processes, so ensuring their efficiency and longevity is paramount. One of the most effective ways to extend the lifespan of your industrial compressor is by using high-quality parts. In this article, we explore the importance of quality components and how they can help improve the performance and durability of your compressor.

Understanding the Role of Industrial Compressors

An industrial compressor is responsible for pressurizing gases, enabling processes such as refrigeration, pneumatic power, and air conditioning. It’s a highly complex system that includes many components that work together to deliver reliable performance. These parts are subjected to high stress, heat, and wear, making the longevity of the compressor heavily reliant on the quality of its components.

Why Quality Industrial Compressor Parts Matter

When it comes to industrial compressors, the parts you choose can significantly affect the unit’s operational efficiency and durability. Substandard components can cause inefficiency, frequent breakdowns, and higher maintenance costs. Conversely, high-quality parts ensure better reliability and a longer service life. Here’s why quality industrial compressor parts are essential:

- Improved Efficiency: High-quality parts are designed to function at optimal levels, reducing energy consumption and preventing unnecessary strain on the compressor. This leads to lower operational costs and a more sustainable performance.

- Reduced Downtime: Using premium parts can drastically reduce the frequency of malfunctions and downtime. This is particularly important in industries where compressor failure can lead to costly delays in production.

- Enhanced Durability: Quality components are made from durable materials that can withstand the harsh operating conditions of industrial compressors. They are less prone to wear and tear, which directly contributes to the extended lifespan of the compressor.

- Better System Compatibility: Using the right parts ensures that all components work in harmony with each other. Mismatched or inferior components can lead to poor performance, accelerated wear, or even system failure.

Key Industrial Compressor Parts That Impact Longevity

Several critical components within an industrial compressor play an essential role in determining its efficiency and lifespan. Using high-quality replacements or upgrades can make a significant difference. Some key parts to consider include:

- Piston Rings: These are responsible for maintaining pressure within the compressor. Premium piston rings offer better sealing and wear resistance, ensuring long-lasting performance.

- Valves: Valves control the flow of gas and are crucial for compressor efficiency. High-quality valves reduce the likelihood of leaks, improving the overall performance and lifespan of the compressor.

- Bearings: Bearings support the moving parts of the compressor, reducing friction. Quality bearings contribute to smooth operation and prevent overheating, which can cause premature failure.

- Filters: High-performance filters help maintain clean air supply and protect other components from contamination. By using top-tier filters, you reduce the risk of damage from debris or moisture buildup.

Regular Maintenance and the Importance of Quality Parts

Even with the best industrial compressor parts, regular maintenance is still crucial for ensuring long-term reliability. Maintenance schedules should include:

- Routine Inspections: Regular checks of components like belts, filters, and valves help detect wear before it becomes a significant problem.

- Lubrication: Proper lubrication reduces friction, ensuring that moving parts operate smoothly. The right lubricants, combined with quality components, minimize the risk of damage due to inadequate lubrication.

- Replacement of Worn Parts: Replacing parts at the first sign of wear ensures the compressor continues to function at its best. Using quality replacement parts will keep the system running efficiently and prevent further damage to the machine.

Conclusion

Maximizing the lifespan of your industrial compressor is largely dependent on the quality of the components used in its construction and maintenance. By investing in top-tier industrial compressor parts and committing to regular maintenance, you can ensure optimal performance and reliability. Ultimately, quality parts not only improve the longevity of the compressor but also result in more efficient operations and reduced downtime, making them a sound investment for any industrial operation.